AUTOMATIC CABLE SCREEN CABLERAKE

ESTRUAGUA

CHARACTERISTICS

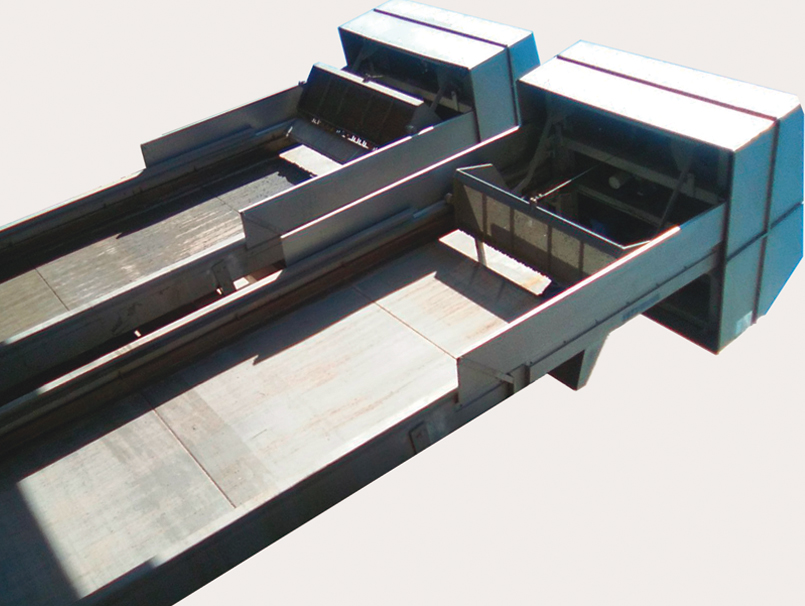

The Automatic cable screen CABLERAKE is prepared to work continuously or in hard conditions in channels of width above 800 mm.

As a correct installation of such machinery, it is recommended to introduce it in channels of very high deepth, in which we cannot implant our hy-draulic or chain screens.

SUCH MECHANIC EQUIPMENT ARE CONSTITUTED BY THE FOLLOWING ELEMENTS: INTEGRAL PARTSFrame.- Monoblock type constituted in hot dip galvanized carbon steel or stainless steel (recommended), is the support to all the assembly of bars, motor system and cleaning assembly, it is also the guide element whereby the cleaning brush travels.

Filtrating screen.- constituted by straight bars of rectangular or triangular section, depending on application.In screens of great dimensions the bars are grouped by modules. The useful pass is variable depending on the project’s needs. All the assembly is dismountable, in order to make a good maintenance or substitution easier. Built in stainless steel.

Powering.- formed by engine drive, powers the main axis where two cable wrapping are assembled, the displacement of the cleaning brush is per-formed by the action of two stainless steel cables that pull it.

Cleaning brush.- the brush’s displacement in slightly inclined direction is displaced over guides located in the same frame. In descendant opera-tion, the brush goes separated by the screen’s bars, which is introduced inside them (as it may apply) when reaching its lowest position, starting the ascending travel, dragging the trapped solids.A discharge plate allows performing the drop at the desired height.

Discharge.- A nylon scrapper coupled over a metallic profile, supported by two pivoting arms, perform the waste’s drop operation, in function of the operation as well as security

CONTROL AND OPERATION ELEMENTSElectric board.- constituted by a cabinet (Himel). The elements which power the cleaning mechanism are located inside the cabinet.

- A function selector, automatic, stop, manual.

- Start/ stop buttons.-A hourly timed clock.

- A powering control pilot.

- A thermal trigger control pilot.

- A general power switch.

- A net indicator pilot.

The board is protected with a command access key, which guarantees the handling of the screen only and exclusively to authorized staff.

All equipment is manufactured under EC rules, in order to be able to find easily its elements inside the national market.

OPTIONAL WORKING EQUIPMENTS- Endless conveyors (Sfh)

- Endless carrier compactors (Sfch)

- Hydraulic compactors (Ch)

- Carrier bands (Ct)